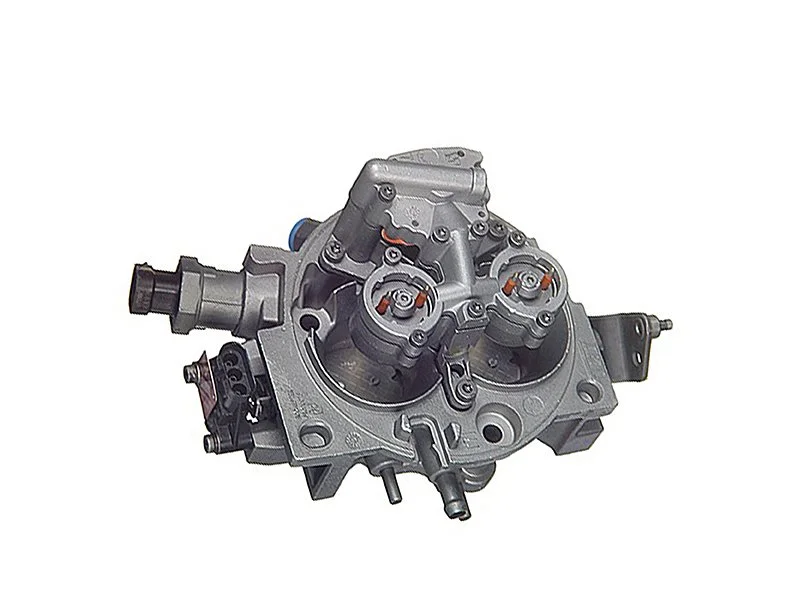

THROTTLE BODY INJECTION UNITS

REMANUFACTURED THROTTLE BODY INJECTION UNITS

At AutoLine, we specialize in precision remanufacturing of throttle body injection units, restoring them to their original equipment specifications. Our meticulous process begins with disassembly, followed by thorough inspection and cleaning of all parts in industrial-grade equipment. Internal components such as gaskets, "O" rings, and filters are replaced, ensuring peak performance.

Housings undergo sandblasting or tumbler processing to restore their finish, while mounting flanges are surfaced for perfect mating with companion parts. During sub-assembly, threads, inlets, and vacuum pipes are inspected and repaired or replaced as needed. Throttle plates are scrutinized and replaced if necessary, and throttle bushings are installed to meet our strict tolerances.

Base assemblies are meticulously checked for vacuum integrity, with any deviations promptly repaired. Throughout assembly, all components undergo rigorous testing, including injectors for resistance, flow, spray pattern, and leaks, as well as throttle position sensors (T.P.S.) and idle air control (I.A.C.) solenoids for voltage and resistance.

Each completed unit undergoes comprehensive flow testing across all operating ranges to ensure precise calibration. Base idle speed settings are adjusted during testing, minimizing adjustments needed during on-vehicle setup.

Packaged in heat shrink with installation instructions, mounting gaskets, and technical bulletins, AutoLine Throttle Body Injection units are ready for seamless installation. Backed by a one-year warranty (90 days for commercial and off-road applications), trust AutoLine for reliability and performance enhancement.

THE DIFFERENCE IS QUALITY

At AutoLine, our commitment to excellence is reflected in every aspect of our remanufactured products. We meticulously craft each item using original equipment castings, ensuring precision and reliability. Any castings that fall short of our rigorous standards are promptly discarded, guaranteeing only the highest quality components make it into our final products.

We meticulously source premium parts to integrate into our remanufacturing process, ensuring durability and performance. Throughout production, each component and sub-assembly undergoes rigorous testing to maintain quality standards. Incorporating production identification into the process further ensures adherence to our strict quality guidelines.

Before packaging, every product undergoes comprehensive testing under simulated operating conditions, ensuring optimal performance upon installation. Additionally, we provide detailed installation instructions and technical bulletins with each product, aiding customers in the installation process. At AutoLine, excellence is not just a goal; it's our standard.

LOOK FOR OUR RED TAG

For over half a century, AutoLine has stood as a trailblazer in sustainable manufacturing. Our mission is clear: to prolong and enhance the functionality of essential auto parts.

Our Red Tag symbolizes our daily efforts to minimize negative environmental impacts, conserve resources, and prioritize social responsibility throughout our entire manufacturing process.

PRODUCT GUARANTEES

QUICK SEARCH

-

AutoLine Products Ltd. - New and Remanufactured Auto Parts

-

Login through your Lilypad account. To request access, please contact Autoline.

-

Find your sales specialist for you region.

-

Find a Warehouse in your region.